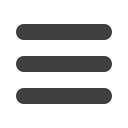

B. - Main Fuel System

On Mikuni VM - type carburetors, the pilot system and the main system

are of the independent commotion. The fuel low in these two systems is

shown in Fig.5 Bleed and primary needle jets can be used on 2 or 4

stroke, use what style achieves proper fueling for your application. It is

important to note (Fig. 5) that the main system

mixture delivery is in addition to the mixture delivered by the pilot

system. Therefore, adjustments to the pilot system should be made

irst, as they will affect the adjustments to the pilot system should be made

irst, as they will affect the adjustment of the main system to a

diminishing extent as the throttle is opened from 1/4 to full throttle.

Primary Type (Fig.6)

When the throttle valve is opened about 1/4 or more, the velocity of air

lowing through the needle jet (10) increases and also the vacuum

increases to the point where fuel can be sucked in. When the opening of

throttle valve (1) is between a quarter and three quarters, fuel passes

through the main jet (9) and, after being metered in the clearance between

the needle jet (10) and the needle (11), it is mixed with air that is metered

by the air jet (12) and atomization of the fuel is accelerated.

The mixture is then

injected, after mixing

with air lowing through

the main bore (7),

to the engine in the

optimum air-fuel ratio.

During this process of

operation, the cutaway

of the throttle valve

serves to control the

vacuum on the needle

et, thereby regulating

the amount of fuel that

is injected to the en-

gine. When the throttle

valve is opened more

than three quarters

high speed operation,

fuel is metered chiely

by the main jet (9).

Bleed Type (Fig. 7)

The construction of the bleed - type (10) main fuel system is the

same as that of the primary type, except for the bleed holes that

are provided in the needle jets.

In the case of the primary

type, air which comes from

the main air jet is mixed

with the raw fuel after it has

been metered by needle jet

and needle. This atomiza-

tion take place behind the

nozzle screen or shroud

above the needle jet outlet.

The bleed type on the other

hand is designed to bleed

the air coming from the main

air jet into the body section

of the needle jet where it is

emulsiied with the fuel com-

ing up from the bottom.

The needle jet and needle

then meter a blend of air/fuel,

resulting in a iner atomiza-

tion and generally leaner

mixture than the same size

primary type needle jet.

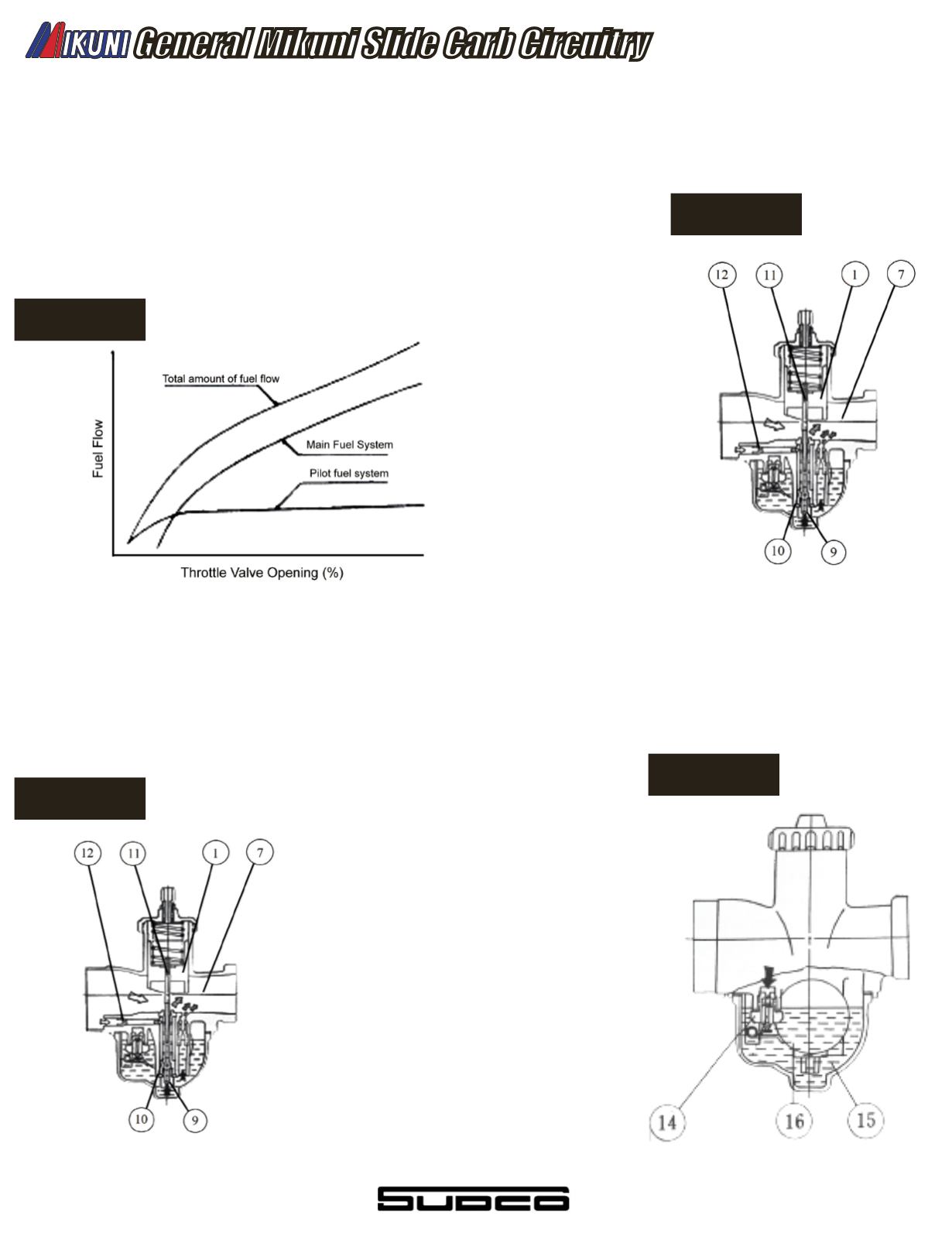

C. Float System (Fig.8)

The loat system serves to maintain a constant level of fuel in the

bowl. Fuel lows through the needle valve (14) and enters the loat

chamber (15). As the fuel enters the loat chamber, the loat

(16) moves upward to its per-determined level because of buoyancy.

When the fuel reaches the per-determined level, the needle valve

begins to close due to the lever action of the loat arm rising as

the loat attains buoyancy, thus shutting off supply of fuel.

The fuel level in the

bowl controls the

amount of fuel which

is metered to make the

optimum fuel mixture.

For example, too high a

level allows more

fuel than necessary to

leave the needle jet,

enriching the mixture.

Too low a level results

in a leaner mixture,

as not enough fuel

leaves the needle jet.

Therefore, the pre-

determined fuel level

should not be changed

arbitrarily.

General Mikuni Slide Carb Circuitry

Figure 7

Figure 5

Figure 8

Figure 6

538