A. - Pilot Jet and Low Speed Fuel System

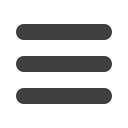

(Fig.15 & 16) (Air Screw type carburetors only)

In the low speed fuel system of the carburetor, the pilot outlet

and the bypass have holes whose size is in relation to the main bore of

the carburetor. Hence, the adjustment and selection of the pilot jet and

the air screw is important. Turn the throttle a little at no-load operation

and see if the engine revolution increases smoothly. If the pilot is

too small, increases in the engine speed will be slow and irregular. Too

big a pilot jet, on the other hand, would give rise to heavy exhaust

smoke as well as a dull exhaust noise. If you cannot maintain the

speed in the range of 12-25 mph with the throttle held, the pilot is too

small.

Selection and setting of the air screw should be made in the

following manner. First, warm up the engine adequately and set the idle

screw so that the engine revolution at idling will be about 10-20%

higher than the number of revolution you are aiming at. Then, tune the

air screw left and right (between 1/4 and 1/2 turn) and select the position

where the engine revolution reaches the maximum. Adjust the idle

screw to bring down the engine revolution to your target speed for

idling. After this adjustment of the idle screw is made, select once more

the position where the engine revolution reaches the maximum, by

turning the air screw left and right (between 1/4 and 1/2 alternately). At

this point, attention should be paid to the following points.

1) If there is a certain range in the opening of the air screw where fast

engine revolution can be obtained, (for instance, the number of revolutions

does not change in the range of 1-1/2 to 2.0 turn), for better performance

you should select approximately 1-1/2 turn.

2) To determine the “fully closed” position of the air screw, turn the air

screw slightly. Excessive tightening of the air screw would damage the

seat. The position where the air screw comes to a stop should be consid-

ered the “fully closed” position. The maximum number of turns in the open-

ing of the air screw must be limited to 3.0. If the air screw is opened over

3.0 turns, the spring will not work and the air screw can come off during

operation of the vehicle. Fig. 16 shows the fuel low curve in relation to the

opening of the air screw.

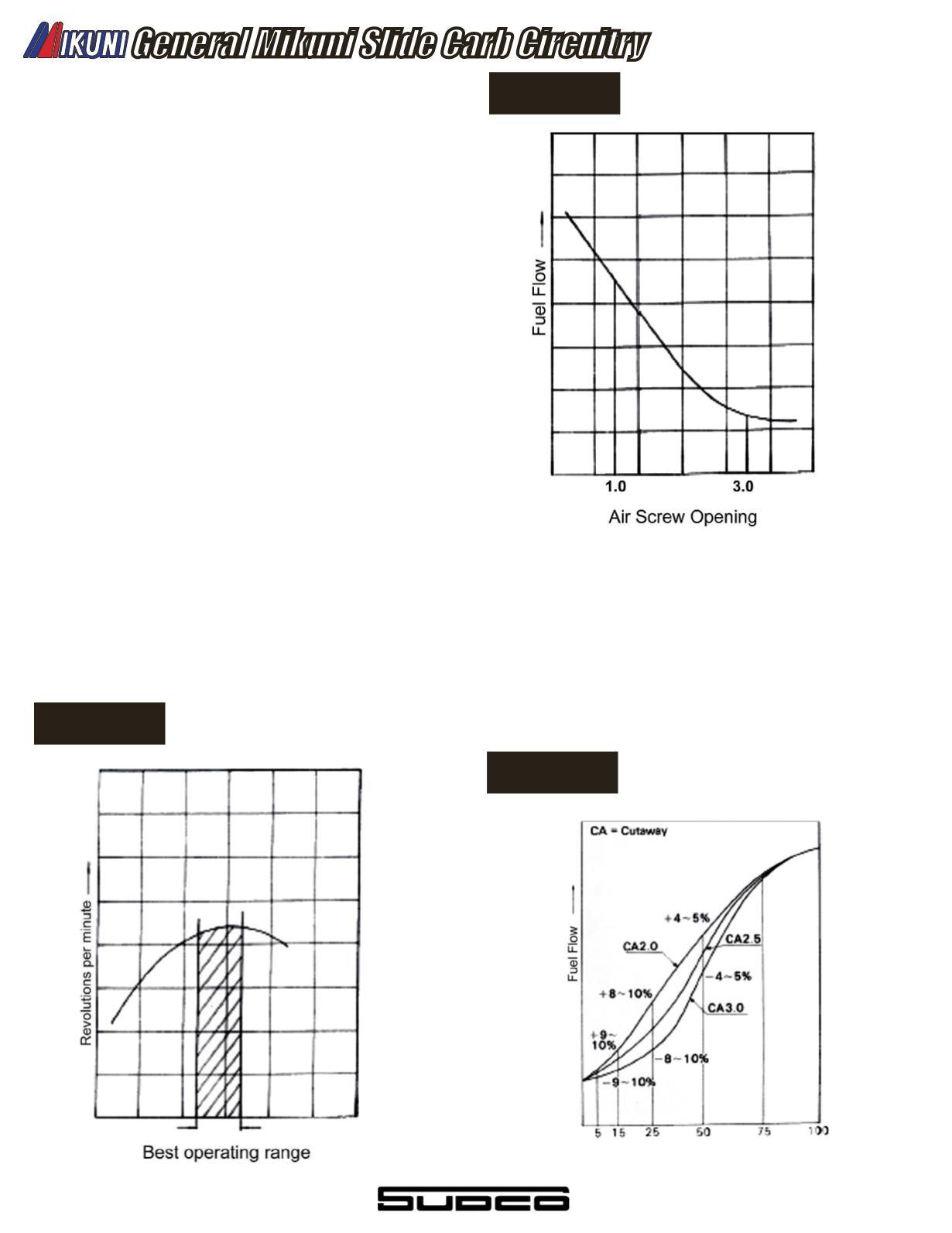

B - The Cutaway Size of the

Throttle Valve (Fig.17)

The size of the cutaway of the throttle valve affect the air-

fuel mixture ratio when the degree of the throttle valve opening is

between 1/8 and 1/2, especially in the range of the 1/8 and 1/4 opening.

As the cutaway gets larger in size, with the throttle valve opening

kept unchanged, air inlow resistance is reduced and causes the

amount of air intake to increases, resulting in a lean mixture. On the

other hand, the smaller the size of the cutaway, the richer the air-fuel

mixture will become. Interchange of the cutaway is made, when the

low speed fuel system is out of balance with the main fuel system.

General Mikuni Slide Carb Circuitry

Figure 16

Figure 15

Figure 17

540