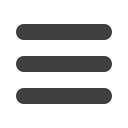

C- Selection of NEEDLE

(Fig. 13 & 14)

A carburetor

with a piston -type throt-

tle valve is also called

a variable venturi-type

carburetor. In this type

of carburetor, the needle

jet and the needle serve

to control a proper air-

fuel mixture ratio during

the so-called medium

throttle valve opening

(between 1/4 and 3/4

opening). The right

combination of needle

jet and needle will have

a major bearing on the

engine performance

at partial load. The jet

needle tapers off at one

end and the clearance

between the needle and

the needle jet increases

as the throttle valve opening gets wider. The air -fuel mixture is controlled

by the height of the needle positioning clip that is inserted into one of the

ive slots provided in the head of the needle. The variation of fuel low

based on the height of the clip is shown in Fig. 13.

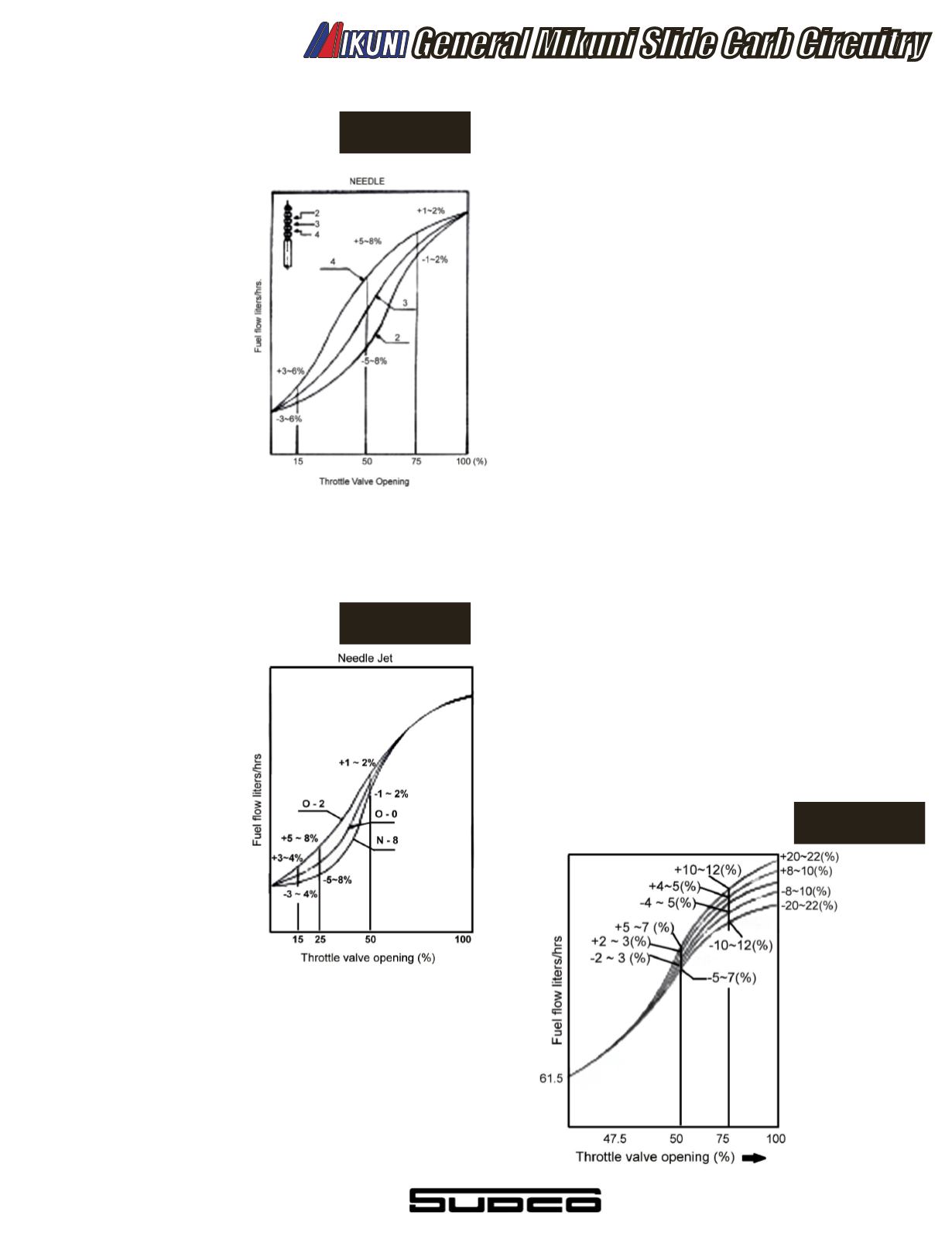

Generally, it is easier

to evaluate and select

a needle jet than it is to

select a jet needle. The

reason is taht he needle

jet size are arranged

on a linear scale, with

each size increasing

in increments. (For

a thorough explana-

tion of needle jet sizes

please refer to Chapter

5) Jet needles are not

cataloged according to

a linear size pattern or

a rich lean scale. The

most effective way to

determine the needle

jet / jet needle relation-

ship is to visualize the

jet needle as a tool for

setting the fuel delivery

curve, or the it shape

of the fuel delivery ac-

cording to the throttle opening. The needle jet controls the fuel delivery

rate, either increasing or decreasing the fuel delivery according to the

proile of the needle being used. Sudco suggests that initially, experi

-

ments should be limited to changes in needle jet size. Once a satisfactory

size has been identiied, experiment with needle clip position to obtain

the best driveability and roll-on performance. if one is working with an

O.E.M. Mikuni carburetor, it is safe to assume that the manufacturer has

already selected the proper needle or “fuel curve” for that motorcycle and

changing the needle proile will complicate the tuning process Once the

correct needle jet size has been identiied and it becomes apparent that a

change in needle proile is necessary, then refer to the needle dimension

charts in Chapter 5.

To evaluate the performance of the needle jet, run the motorcycle

in the third

gear at 1/4 throttle, taking note on how the engine

accelerates from 1/4 to 1/2 throttle only. The engine should

respond cleanly and crispy without sputtering or bogging. It may

be useful to try experimenting with clip positions to decide if a

problem is a rich or lean condition. If the engine responses is

better at a lean clip position, it may be necessary to change

to a leaner needle jet. Sudco suggests that it is best to use as

lean a needle jet as possible, as this component will have the

greatest effect on fuel economy, emission, and general driveability.

If a leaner needle jet is installed and there is no negative impact on

performance, and no positive effect, continue working in the

direction of “lean” until there are negative results and go back up

one size.

D. - Selection of the Main Jet

First, do the following on a lat road.

1)

Select the largest main jet ( the limit of a rich mixture) which

can give you the maximum speed). In this case, select the engine

speed according to the dimensions of the test course.

2)

Compare the gain in speed of 25-30 MPH to maximum

desired speed, by using different sizes of main jets.

3)

Check the exhaust fumes and read the spark plug (selection

of the spark plug should be made based on the thermal value

that would best suit power output of the engine.

Next, compare in the racing course, the test results you

obtained from above. The points to be checked, among others, are:

1)

Smooth and steady operation of the engine at as high a

speed as possible under varying operating conditions

such as shifting of the gears, changes in road conditions,

ascending and descending slopes, etc.

2)

Sustained operation at low speeds and at heavy engine load.

3)

Sustained operation at high speeds (without knocking or seizure).

CAUTIONS:

Selection of too lean amain jet may cause

severe engine overheating, and subsequent piston seizure.

Fig. 12 shows comparison of fuel low curves. The straight

line is for Model C main jet and the dotted line for Model A

and B main jets. In each model of main jet, different sizes

within the range of +10% were tried.

General Mikuni Slide Carb Circuitry

Figure 17

Figure 14

Figure 12

541