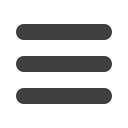

D. - Starter System (Fig.9)

Rather than a choke, an

enrichener type starter

system is employed for

Mikuni carburetors. The

enrichener starter type,

fuel and air, for starting

the engine are metered by

entirely independent jets.

The fuel metered by the

starter jet (17) is mixed

with air and is broken into

tiny particles in the emul-

sion tube (18). The mixture

then lows into the plunger

area (19), mixes again

with air coming from the

air intake port for starting

and is delivered to the

ngine in the optimum air-

fuel ratio through the fuel

discharge passage (21).

The enrichener is opened

and closed by means of

the starter plunger (22). Since the enrichener is constructed so as to

utilize the vacuum of the inlet passage (20), it is important that the

throttle valve is closed when starting the engine.

4. TUNE UP & CARBURETOR SELECTION

Turning up normally means a process of accurate and careful adjustments

to obtain maximum engine performance. Although, it means is a broad

sense, an economical improvement fuel consumption. Improvement of

power output of the engine depends on the amount of air drawn into the

cylinder per unit time. A practice generally followed for engine tune-up

includes:

1.) To improve suction eficiency and exhaust eficiency

by remodeling the intake and exhaust system.

2) To improve combustion eficiency by raising the compression ratio

3) To increase the number of revolutions by adjusting the ignition

timing

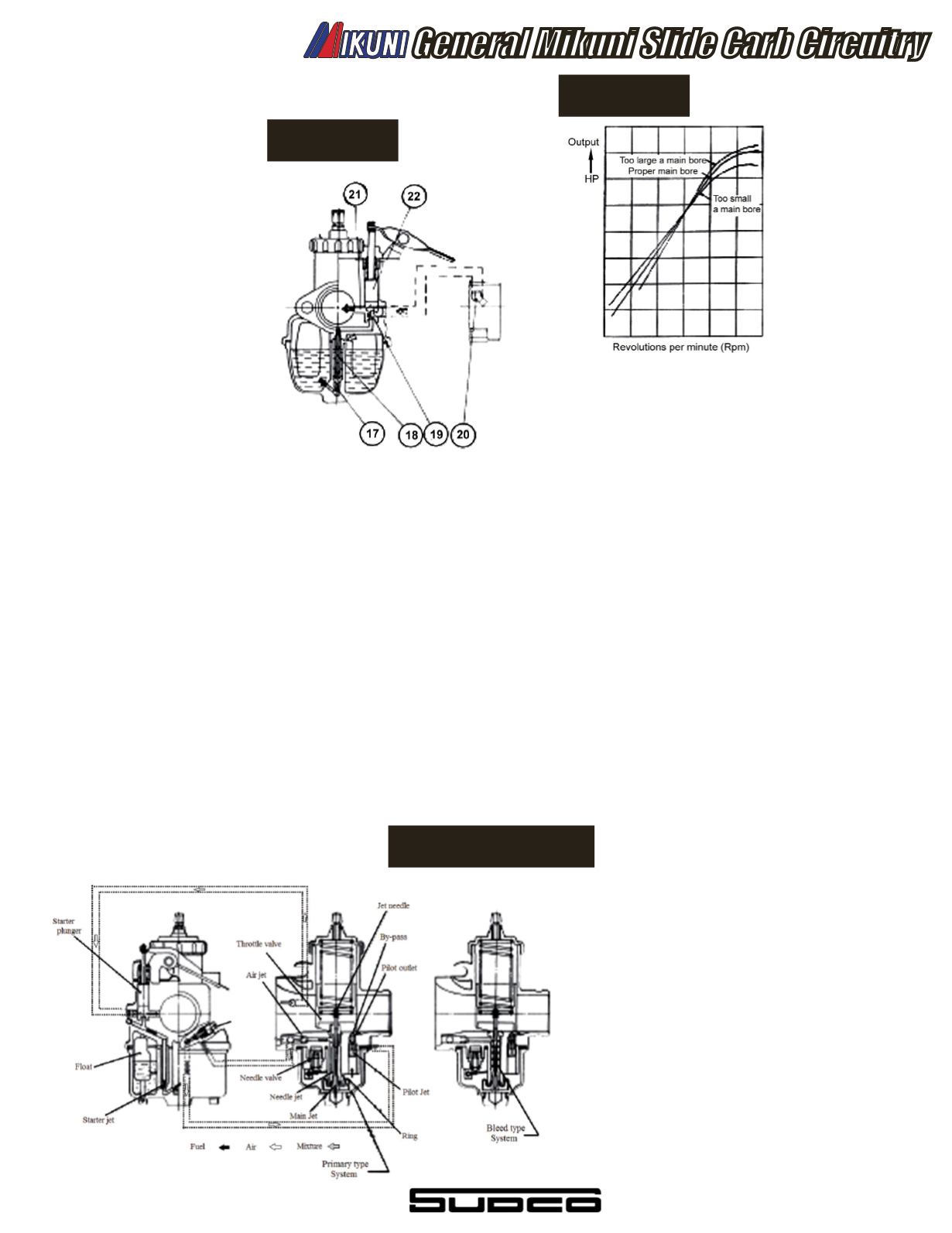

A. - Carburetor Main Bore Size Selection

One of the main prerequisites for improving the output is to

use a carburetor with a large a main bore as possible.

However, a large main bore alone does not necessary improve

the output. As shown in Fig. 10, it is true that a large main

bore improves the power output in high speed range. However,

in slow speed range, the output may drop. The main bore size

selection should be determined by various factors such as: (1)

whether the vehicle is intended for racing, (2) the design of the

engine, (3) rising technique of the rider, (4) the rider’s preference,

etc. In addition, the maximum output, the maximum torque, and

the maximum number of revolutions for stable engine operation

must also be taken into account Fig. 10 shows the values which

we have obtained throughout experience over the years.

Since the engine comes in a wide variety of types, the values

given in Fig 10 should be taken only as reference values.

5. Carburetor Setting

Once the main bore size of the carburetor is

determined. a test (normally referred to as setting

or matching) to select the proper jet or setting part

should be made. The size of the jet is determined

be measuring the output in a bench or in a chassis

dyno test. For racing it is best to determined the

proper size of the jet on the racing course.

The following points must be taken into account:

1) the altitude (atmospheric pressure),

temperature and humidity of the racing course.

2) The operation of the engine based on the topogra-

phy of the racing course.

3) Generally, carburetor tuning is done in four stages:

idle, low speed, mid-range, and high

speed in that order. With the Mikuni, each stage is

controlled by a separated component simplifying the

tuning process.

The engine cylinders need to take suficient air

and fuel mixed in proper amounts. The function

of a carburetor is to prepare and supply a mixture

of fuel vapor and air to the engine cylinders in the

proper ratio for eficient combustion.

General Mikuni Slide Carb Circuitry

Figure 9

Figure 10

Air/Fuel Mixture

539