6. MAINTENANCE

A carburetor consists of various precision machined parts such jets,

needles, valves, etc. Therefore, care should be exercised, when

removing

jets or disassembling the carburetor for cleaning.

1)

Proper tools should be used for disassembling and reassembling

of jets. Handle watch part carefully to avoid scratches, bending, etc.

2) Wash the jets and the carburetor properly in solvent and blow

them out with compressed air.

3)

For carburetors whose main jet can be replaced from the outside,

an “O” ring is used to prevent leakage of fuel. When you it the “O’

ring, apply a little lubricant or fuel.

4)

It is important to maintain the fuel level in the carburetor. Do not

touch the loat arm, when disassembling the carburetor. If the loat

arm is bent accidentally, adjust the height of rib to the speciic mea

-

surement (refer to Fig 18).

7. TUNING CARBURETOR RACING

The maximum output of the engine depends on:

1)

The amount of air drawn into the cylinders

2)

Whether an air fuel mixture is delivered to the cylinders

in a proper ratio.

Since the amount of air that is drawn into the carburetor

varies with the temperature, the atmospheric pressure, humidity,

etc., the mixture ratio is also changed. It is important; therefore, that

the fuel low be adjusted in accordance with the altitude of the racing

course and meteorological conditions prevailing.

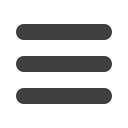

A. - Incoming Air in Relation

to Meteorological Conditions

The amount of air drawn in to the cylinders is inluenced by such

factors as the altitude, the temperature, the humidity, etc. Supposed

that the amount of air sucked into the cylinders at an elevation of

zero is taken as 100 (the temperature and humidity in this ease are

considered constant). The amount of air in question decreases in

proportion to a rise in elevation as shown in Fig.19. Reduction in the

amount of air drawn into the cylinders changes the air-fuel mixture

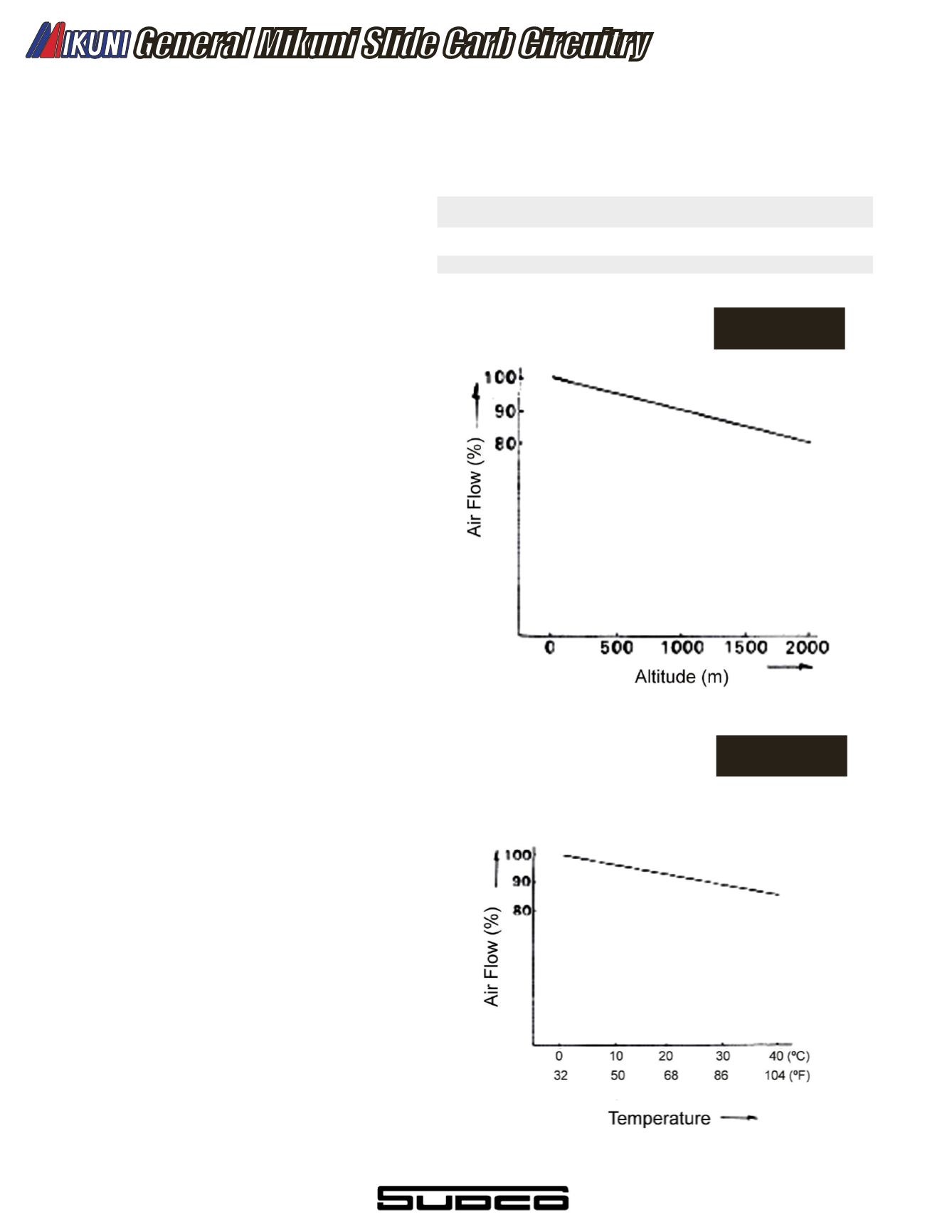

ratio, with the result that the power output drops markedly. Fig.20

shows the relation between a rise in temperature and the amount of

air drawn into the cylinders (in this case, the atmospheric pressure

(elevation0 and the humidity are considered unchanged and the

amount of air going into the cylinders at 32 degrees F (0 degrees

C) is taken as 100. In this case of the engine for racing where the

maximum output is constantly called for, it is to tune up the engine

by making a matching test the carburetor in accordance with the

temperature and other conditions on the racing course.

Model VM16-519 VM18-144 VM20-273 VM22-133 VM26-8074

H

(mm)

24~26 20~22

20~22 24~26 15~17

VM26-606 VM30-83 VM34-168 VM36-4 VM38-9 VM44-3

22~24 22~24 22~24

17~19 17~19 17~19

General Mikuni Slide Carb Circuitry

Figure 19

Figure 20

542