HS40 Carburetors

(General Tuning Procedures)

Tuning the Jet Needle

Like the idle circuit, the jet needle, within its range of opera-

tion has gradually increasing effect on fuel mixture as the throttle is

opened. From about 1/4 throttle, where the tapered section of the needle

leaves the mouth of the needle jet, the jet needle has a major effect on

the amount of fuel entering the engine. Between 1/2 and 3/4 throttle the

needle’s inluence is greatest and it controls most of the fuel low.

All jet needle and main jet testing should be done with the

engine near the middle of its rpm range. Start acceleration tests at

about 50 mph. The best jet needle position will give the strongest accel

-

eration.

With the engine at operating temperature, accelerate at 1/2 to

3/4 throttle, in top gear from 50 mph or so. If acceleration seems soft or

lat and the engine is slow to respond when the throttle is quickly

opened from 1/2 to 3/4 throttle position, the mixture is too lean. Raise

the jet needle one notch and repeat the test.

On the other hand, if acceleration is crisp but the engines

hesitate or staggers as the throttle suddenly shut down from 3/4 to 1/2

throttle, the mixture is too rich. Lower the needle one notch and repeat

the test. The jet needle position will be near correct when acceleration

is crisp at mid rpm yet the engine does not load up dining throttle

shutdown.

Tuning the Main jet

You could in fact remove the main jet from our Mikuni HS40

and the engine would run ine until the throttle was near the 3/4 mark.

The needle and needle jet restrict the amount of fuel getting into the

engine until about that point. There is no need to change main jets if a

mixture problem exists below the 3/4 throttle position.

The main jet is the last jet you need to deal with, and it is the

easiest to get right. The most effective method for getting the main jet

right is to measure the time required to accelerate between two points.

The start and end markers should be spaced so that starting at about

35 mph at the irst marker will have you going past the second at near

55 mph.

Set up markers that are far enough apart, on a safe road, to

meet the conditions mentioned above. When pass the irst marker roll

the throttle fully open and have a friend (it’s easier with help) measure

the time need to her to the second marker. The jet that gives the

shortest time is the correct jet. This method is simple but effective.

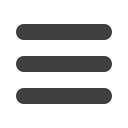

Accelerator Pump Tuning - Fig 9

The beginning point of the pump stroke is adjusted with

adjusting screw #1 on the white plastic pump lever. To start the pump

sooner, back the crew out. Turn the screw in to make the pump start its

stroke at a larger throttle opening. Most engines will perform best if the

pump begins its stroke as soon as the throttle is moved from the idle

position.

The end of the accelerator pump stroke is adjusted by the

adjusting screw #2 located on the top of the carburetor just behind the

pump lever. Best performance is generally achieved when the pump

stroke ends before 3/4 throttle.

It is important that the nozzle’s direction be correctly set. The

nozzle is held in position by the friction of its o-ring and can be turned

quite easily with a pair of long nosed pliers. Rotate the nozzle until the

fuel stream strikes the needle. This will ensure an even distribution of

fuel between the front and rear cylinders. Nozzle adjustment should be

made with the engine stopped and with a minimum of pump strokes to

avoid looding.

Fine Tuning the Pilot System

Note:

Before you apply any of the information in this section be

sure that the basic pilot system is correct. Be sure that the engine idles

smoothly with the mixture screw between one and three turns out from the

seated position.

The pilot and pilot air jets have slightly different effects on mix-

ture strength within the effective tuning range of the pilot system: 0 - 1/4

throttle. When you change the pilot jet, it will have a slightly greater effect

on mixture strength at zero throttle than it will be at 1/4 throttle.

On the other hand, when you change the pilot air jet, it will have

a slightly greater effect above 1/8 throttle than it will below that setting.

If your engine has slightly soft acceleration just as the throttle is

raised from the off idle position, the size balance between the pilot jet and

pilot air jet may be incorrect. If the softness is more pronounced when the

engine is at normal running temperature, install a larger (leaner) pilot air

jet. if there is minor coughing or “popping” through the carburetor when

the engine is cool, install a smaller (richer) pilot air jet.

After you have changed the pilot air jet, you will need to re-

adjust the mixture screw. If the new mixture screw adjustment is outside

idle at more than three turn range, change the pilot jet. If the mixture

screws give idle at more than three turns, install the next larger (richer)

pilot jet. If on the other hand, correct idle requires less than one turn, ir

the next smaller pilot jet.

It is unlikely that changing the pilot jet will have an adverse

effect on the pilot air jet requirement.

Important Note: Detecting Air Leaks

While the engine is idling, spray carburetor or brake cleaner

around the areas of the intake tract where there are mating sur-

faces, i.e., cylinder head to compliance itting, If there is an air leak

the engine RPM will increase or decrease when the spray covers

or is drawn through the leaking area into the engine.

Fig. 9 - Accelerator Pump Tuning

548