Super BN

Tuning

Adjusting pop-off pressure

Pop-off pressure is adjustable by replacing the arm spring

with one of a different gram rating. Sometimes, in order to achieve the

desired pop-off pressure, it is also necessary to change the needle

valve size; keep in mind that it’s always best to use the smallest needle

valve size to obtained the correct pop-off pressure.

Measuring pop-off pressure

You can measure pop-off pressure with a “Pop-off” pump,

available from Mikuni through your dealer, or you can get a relatively

good indicator of pop-off pressure by simply using the needle valve and

arm spring guide in this manual. Pop-off pumps are available in three

ranges: 0-30psi., 0-60psi., and 0-100psi. For most performance appli

-

cations the 0-30psi pump is appropriate. Pop-off pressures, in psi., from

needle valve size and arm spring combinations:

Checking pop-off with a pop-off pump/

gauge

1) Attach the pump to the fuel inlet nipple.

2) Cover, or in some way plug the fuel return nipple.

3) Remove the regulator diaphragm to observe the needle valve.

4) During testing, it is important to obtain consistent readings.

To accomplish this, it is necessary to keep the needle valve wet.

Use WD-40 or something similar to wet the needle valve.

Note: Don’t use gasoline because of the tire hazard.

Protect your eyes from the spray when the needle pops open.

5) Pressurize the carb with the pump until the needle valve

pops open, being careful to note the indicated pressure.

Test the valve 3 times to assure an accurate reading.

An indication that your pop-off needs to be adjusted is

a lean hesitation when you open the throttle from idle; in the ex-

treme, the engine may even die. It is much easier to detect a lean

pop-off than it is a rich one, so it si wise to adjust your pop-off until

you get it too lean and then back up until the lean hesitation

disappears.

NOTE:

It is recommended that you do not use

too large a needle valve for your application. Many tuners

recommend using a 2.3 or 2.5 needle valve in all cases.

Actually, we recommend using the smallest needle valve

that gives you the correct pop-off pressure for your engine.

A 1.5 needle valve can low the maximum amount of fuel

that the Super BN can pump, so the only reason to use a

large needle valve is to obtain the correct needle valve and

arm spring combination (pop-off) for your watercraft.

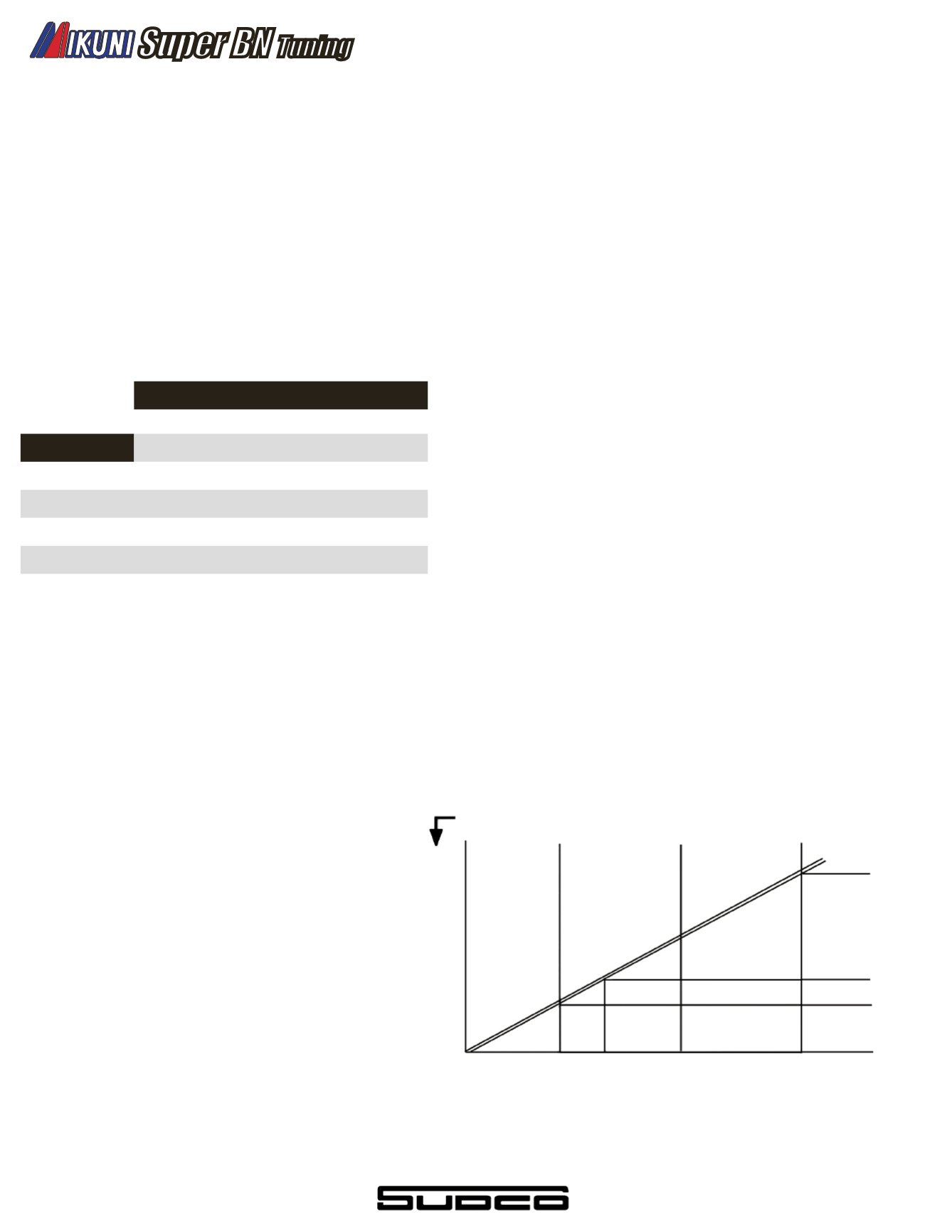

High Speed Jet / Throttle Position and Jetting

The high speed jet begins contributing fuel at about 3/8 throttle,

overlapping the low speed jet. The high speed jet is the primary tunning

component from 1/2 to 3/4 throttle. As you have probably noticed, tuning

circuit operations are denoted in fractions of throttle openings. The reason

for this is simple: Carb jetting does not relate to engine rpm or the boat’s

speed, it only recognizes how far the throttle has need opened; each

circuit of the carb responds in turn. This is why it’s very important, when

trying to diagnose a carb problem, that you identify at which throttle open-

ing the problem occurs, in order to adjust the appropriate circuit.

The procedures for testing for the correct high speed jet size

is the same as for the low speed, except that you should now hold the

throttle fully to check engine response. If the engine hesitates, the carb is

lean. If the engine takes a second or two to clear out and then accelerate,

the carb is too rich. In either case, make the I appropriate jet change and

do the complete test again.

High Speed Adjuster

The high speed adjuster is the last circuit to adjust. It primarily

controls fuel delivery from 3/4 throttle to wide open throttle. Turning the

screw clockwise reduces fuel low, counter clockwise increases fuel low.

The maximum fuel low is achieved at three turns out from

closed.

To test the high speed adjuster it is recommended that you

start with a fresh set of spark plugs, to get quicker plug readings, Unless

you have an exhaust gas temperature gauge, you will have to rely on plug

readings.

You will need to be in an area where you can hold the throttle

wide open for several minutes then chop the throttle and stop the engine

just prior to removing the plugs to read the,. Ideally, you’re looking for a

nice brown color on the electrode.

Another indicator of proper adjustment is a maximum rpm reading

on a tachometer. If the carb is lean or rich, it won’t pull as high an rpm read

-

ing as when it’s right on.

Fuel Flow Chart

554

Throttle Position

Idle 1/4 3/8 1/2 3/4 Full

High Speed

Adjuster

Low Speed

Jet

Pop-off Pressure

Low Speed Adjuster

High Speed

Jet

Percentage of Total Fuel Flow

100%

66%

33%

1%

Pop-Off Arm Spring (color & strength)

Gold

Dull Silver Black

Shiny Silver

Needle Valve Size

115 grams 95 grams

80 grams

65 grams

1.5

55 psi.

43 psi.

38 psi.

32 psi.

2.0

32 psi.

25 psi.

21 psi.

18 psi.

2.3

22 psi.

20 psi.

17 psi.

15 psi.

2.5

19 psi.

17 psi.

14 psi.

12 psi.