Super BN

Introduction

Introduction to Super BN Carbs

The Super BN Carburetor for high performance application is the latest in a series

of watercraft carburetors from Mikuni. the super BN earns its name because of the

increased performance it delivers over previous Mikuni BN Carbs.

What differentiates the Super BM from previous BNs?

1) The fuel pump and jet sections are separate for easier maintenance.

2) It has an integral fuel ilter.

3) The fuel pump capacity is increased by almost 20%.

4) Air low is increased by 9%.

5) It is easily tunable with replaceable jets (in a wide range of sizes) and an

array of other tuning components.

With the introduction of the Super BN Series of carburetors, Mikuni American has made

a renewed commitment to the watercraft industry by researching carburetor tuning applications

and disseminating this formation to the customer. In the past, jetting information was available

there were sources. With this manual, Mikuni American is able to provide a more reliable and

consistent source of approved technical information.

Carb Installation

CAUTION:

Exercise care when changing carburetion compo-

nents and anytime you work with the fuel system on your water-

craft. work in a well ventilated area. Do not engage the starter

while fuel lines are disconnected. Immediately clean up any fuel

spill that might occur during carb installation.

A:

As when installing any performance product, a degree of

mechanical ability is required. If after reviewing the parts and

instruction you don’t feel that you can properly complete this in

-

stallation and adjustment will save time, money and aggravation.

B:

In mos cases your new Super BN Carburetor will be installed

in

conjunction with an after-market manifold and lame arrestor/air

ilter

system. We recommend using ths manual, together with the

applicable shop manual for your watercraft, and the instructions

from the aftermarket manifold manufacturer to help you with the

installation and tuning of the Super BN Carburetor.

C:

Super BN carbs were designed to, and work best, in the down

draft position. Many turners choose to mount Super BNs in more

of a side draft position. This will work okay, as long as the carbs

are oriented with the pump on top and the regulator portion down,

otherwise the jet portion will constantly drain into the carb making

calibration impossible.

D: How to determine the correct carb size to

use.

The following recommendations are for

performance application:

E: All Applications

1)

Use a new gasket between the carb(s) and the intake manifold.

2)

Use lat washers and self-locking nuts to secure the carb(s).

3)

Be sure that the fuel lines are of the correct diameter for the carb

ittings. Secure all hose connections with cable ties or hose clamps.

4)

If the primer itting is not being used, plug or cap the itting.

5)

When installing the throttle cable, be sure to securely tighten the jam

nuts. Allow free play at the throttle lever. Make sure that the throttle

cable is not pulled open as the handlebars are turned from side to side;

correct the cable routing if necessary.

F: Installing Dual Super BN Carbs

The only Super BN carbs that are factory prepare to be used

as duals are the BN38-34-8075, 8076. Several other models have extended

throttle shafts to make them easier to use as dual; one of the carbs will need

to be modiied slightly prior to use. The modiication consists of removing the

throttle lever, idle stop, spring and sleeve, and then cutting the threaded shaft

end to the desired length. After removing the above mentioned parts, place

both carbs on the manifold and cut enough of the threaded end of the shaft

to allow one eighth inc (0.1257) clearance between the shaft ends: Be sure

to chamfer the sharp edge.

A Mikuni coupling kit, MK-BN/001, is recommended to connect the

two carbs together and synchronize them.

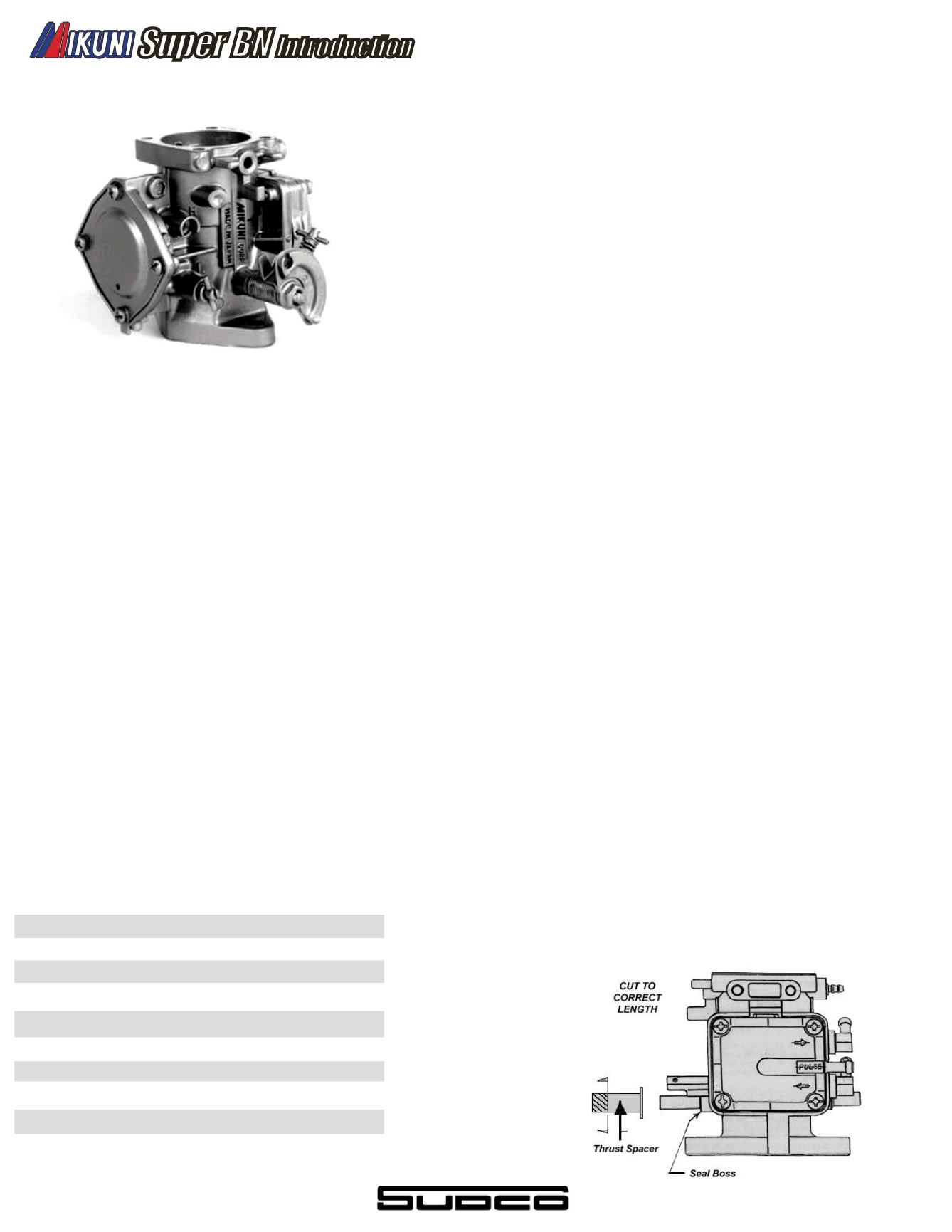

Note: The sleeve that was removed from the carb is actually a thrust spacer

and must be used with the coupler. The sleeve should be shortened to the

correct length and placed between the end of the coupler and the seal boss

(see illustration) to prevent the shaft from moving side to side; this movement

can cause damage to the throttle valve.

G: SYNCHRONIZING DUAL CARBS

1) Place the coupling on the throttle shaft between the carbs and secure

the carbs to the manifold.

2) Back out the idle stop screw until it no longer contacts the throttle

linkage.

3) Position the coupling between the carbs, against the shortened sleeve, and

securely tighten the set

screws on one end only.

4) Use the eraser end of

a pencil or similar blunt

object to push and hold

the throttle valve closed in

the carb without a return

spring. With the throttle

valve held closed, tighten

the remaining screws.

5) Adjust the idle stop

screw ir the desire idle

speed.

Mikuni Super BN46 carburetor

550

1.) Up to 80 hp

SBN 44

2.) Up to 90 hp

SBN 46

3.) 90hp and up

Dual SBN 38, 44, or 46’s

Rotary Valve engines

1.) Limited class

SBN 44/46’s or dual SBN 38’s

2.) Mod class

Dual SBN 44/46’s

Three Cylinder engines

1.) Limited Class

Three SBN 38’s

2.) Mod Class

Three SBN44/46’s

Piston Port and reed valve twin cylinder engines