Carburetor Tuning

530

Jetting Your Slide Valve Carburetors

All Keihin carburetors are pre-jetted for bolt-on

operation. Carburetors are jetted using stock

motorcycles and watercrafts. Any major engine

modiications like higher compression pistons

and racing exhaust systems may require minor

jetting adjustments. The followong is a guideline

jetting in the order given below.

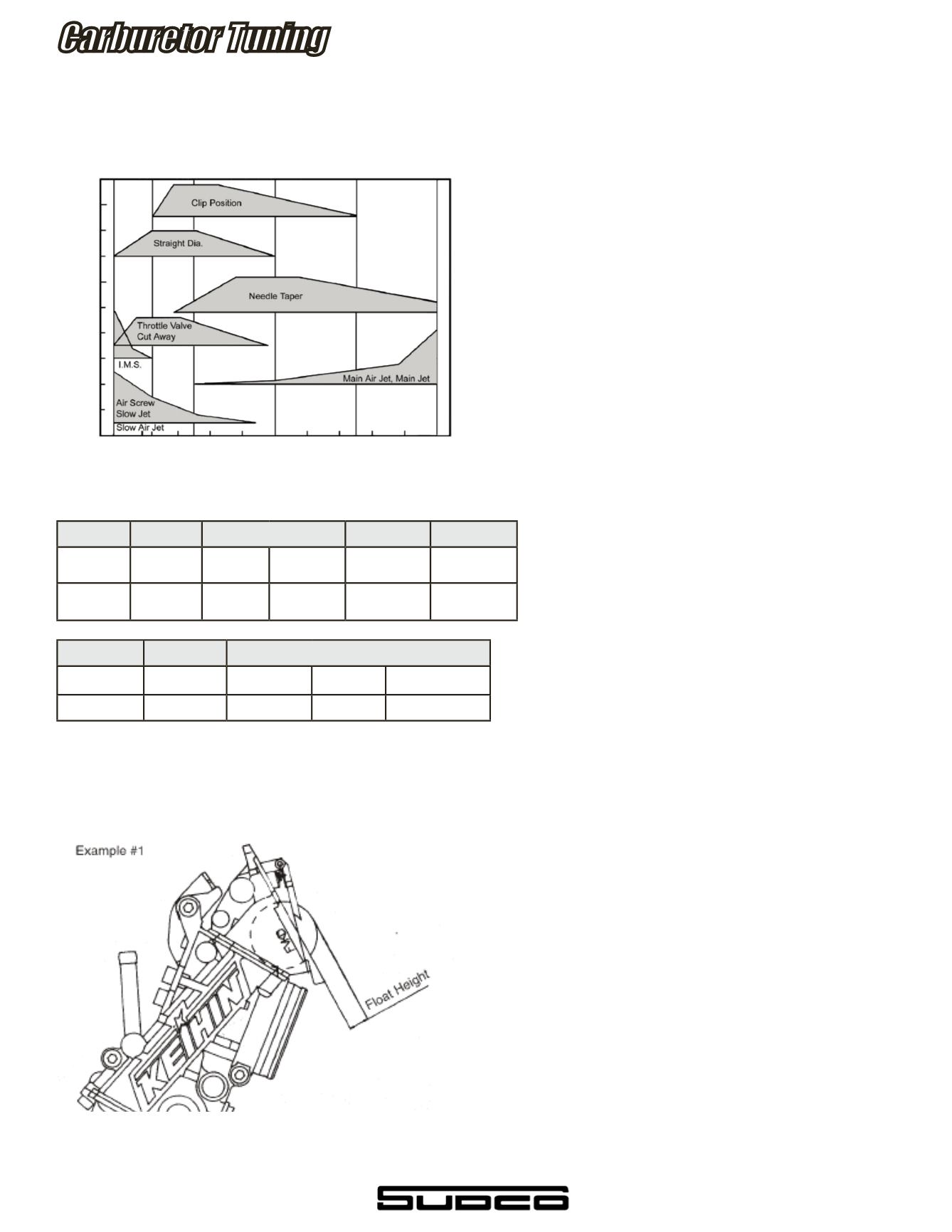

1) CORRECT FLOAT HEIGHT

Before changing any jetting parts, check the

carburetor loats for correct height. Measure

the height from the bottom of the loat to the

carburetor-body gasket surface. Correct

height can be found on the chart. When

checking the loat height, the loat should be

resting, but not depressing, the spring

loaded loat valve pin. This can be done by

tilting the carburetor until the loat tab just

makes contact with the valve pin. If

adjustment is needed, bend the metal tab on

the loat arm until correct height is

obtained. ----- see example #1.

2) IDLE

Set idle speed to proper r.p.m. by adjusting

the IDLE SPEED SCREW. Turn the IDLE

MIXTURE SCREW or the AIR SCREW to

achieve highest speed and best response.

The IDLE MIXTURE SCREW (FCR) controls

fuel delivery to the idle port and the SCREW

is located on the engine side of the

carburetor slide. Turning the IDLE

MIXTURE SCREW out will male idle and

off-idle richer. Turning IDLE MIXTURE

SCREW (CR, PWK, PJ, PE) controls the

amount of air to the IDLE and SLOW

CIRCUIT. The SCREW is located on the air

cleaner side of the throttle slide and turning

the SCREW out will lean the mixture and

turning the SCREW in (clockwise) will

richen mixture.

3) OFF IDLE TO 1/4 THROTTLE

The SLOW JET and SLOW AIR JET are most

effective in this range, use a larger

SLOW JET or a smaller SLOW AIR JET. The

opposite holds true for a leaner mixture.

Calibration Chart

( )

for FCR, CRS,

PWK, PJ, PE

Float Height

NOTE: (See Jetting instruction #1)

for correct procedure.

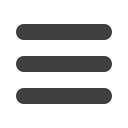

IDLE 1/8 1/4 1/2 3/4 W.O.T.

Effectiveness

PJ PWM

PE

ALL

38 24-38 30-34 36-39

16mm 6.5mm

14.mm20mm 22.25mm

FCR CR

PWK

PD PD

ALL ALL 28 35-39 26-30 36-39

9mm 14mm 19mm 16mm 12.5mm 22.5mm