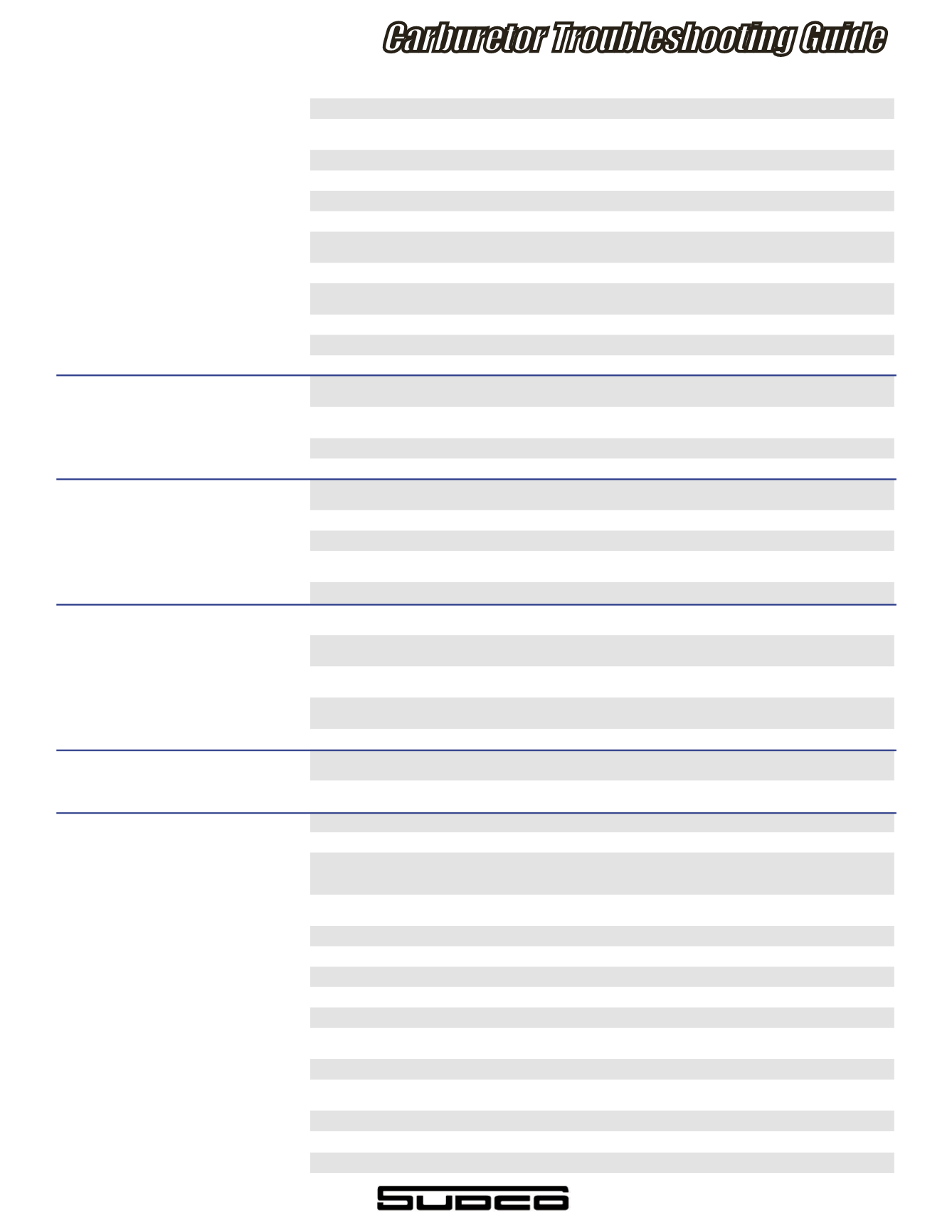

Incorrect use of choke

Correct use of choke

Incorrect air mixture adjustment

Set mixture adjustment screw in accordance with owner’s

manual instructions

Clogged fuel ilter

Clean ilter

Clogged low speed fuel jets

Disassemble carburetor and chemically clean

Clogged vent in fuel jets

Unclog vent or replace cap

Clogged vent in fuel cap

Unclog vent or replace cap

Float stuck

Remove loat bowl, check loat operation and correct or

replace

Float damaged or leaking

Replace loat

Incorrect loat level

Set loat height in accordance with shop manual specii

-

cation

Intake air leak

Check carburetor mounting langes for air leaks

Ignition problem

Repair, replace, or adjust as necessary

Low cylinder compression

Repair, replace, or adjust as necessary

Idle adjustment(s)

Adjust idle RPM in accordance with speciication in own

-

er’s manual or shop manual

Idle speed adjustments are unequal (twin and multi-car-

buretor models using individual throttle stop adjustments)

Equalize throttle stop settings

Clogged idle & low speed air bleed

Disassemble carburetor and chemically clean

All causes listed under “Hard Starting”

Idle speed set too high

Adjust speed in accordance with speciication in

owner’s manual or shop manual

Clogged low speed air-bleeds

Disassemble carburetor and chemically clean

Damaged mixture adjustment needle

Replace mixture adjustment needle

Mixture adjustment needle “O” ring is not sealing (models

using “O” ring)

Replace “O” ring

Damaged mixture adjustment needle seat

Replace carburetor

Idle speed set too high

Adjust idle speed in accordance with speciication in own

-

er’s manual or shop manual

Idle speed adjustment are unequal (twin and multi-carbu-

retor models using individual throttle stop adjustments)

Equalize throttle stop setting

Throttle valve sticking

Clean and inspect throttle valve and return spring. Replace

as necessary

Throttle linkage sticking

Clean and inspect throttle linkage and return spring. Lubri-

cate, repair, or replace as necessary.

Throttle cable blinding

Correct routing or replace cable as necessary

Incorrect air-fuel mixture adjustment

Low speed - Low speed jet size change.

Intermediate - Jet needle height adjustment

Vacuum piston sticking

Clean and inspect vacuum piston and return spring.

Replace if necessary.

Incorrect choke

Correct use of choke

Clogged air cleaner

Clean or replace

Incorrect air-fuel mixture adjustment

Low speed - Low speed jet size change

Intermediate - Jet needle height adjustment

High speed - Main jet size change

Throttle valve not synchronized

(models with two or more carburetors)

Adjust throttle valve synchronization

Clogged fuel ilter

Clean ilter

Clogged fuel jets

Disassemble carburetor and chemically clean

Clogged air bleeds

Disassemble carburetor and chemically clean

Fuel jet loose

Tighten fuel jets

Fuel jet “O” rings leaking (models using “O” rings)

Replace “O” rings

Float stuck

Remove loat bowl, check loat operation, and correct or

replace

Float damaged or leaking

Replace loat

Incorrect loat level

Set loat height in accordance with shop manual

speciication

Vacuum piston diaphragm raptured

Replace vacuum piston assembly

Ignition problem

Repair, replace, or adjust as necessary

Low cylinder compression

Repair, replace, or adjust as necessary

Problem

Hard Starting

Possible Causes

Correction

Poor Idle or Stalling

Idle mixture adjustment is effective.

Carburetor does not respond to

movement of the idle mixture screw.

Slow return to idle

Engine surges when at a constant speed

Engine does not develop full power, or

misses on acceleration

Carburetor Troubleshooting Guide

529