When turning motorcycle carburetors, there are several

procedures and preliminary checks that will make the tuning

and troubleshooting process go smoothly and quickly.

1. In order for carburetors to work properly, the engine must be

in good mechanical condition. All of the following parameters

should be checked in order to proceed with the carburetor tuning.

A.

Compression - all cylinders should be within 10%

of each other according to cranking compression

B.

Valve adjustment/Cam Timing - check valve clearance

according to the factory service manual, consult a qualiied

technician if there is any question about the cam timing.

C.

Ignition Quality - adjust point gap and ignition timing according

to the factory service manual. Double check the

gap and install new spark plug prior to any carburetor tuning.

D.

Air Filter Quality - Check to see that the air ilter is clean

and that all bafles and snorkels are in place, or have been

removed as necessary for increased airlow. In any case,

the air box / air ilter dimensions should be inalized.

E.

Exhaust System - Install all muflers and bafles.

Double check all silencer packing and bafle installation.

Finalize all exhaust system speciications before moving on

to the carburetors. Jetting can vary dramatically according to

mufler / bafle selection.

2. All fuel delivery circuits operate according to throttle

position. In order to determine which there is a problem. Do not use

R.P.M. to determine which circuit to tune. Sudco suggests the use of a

throttle index on the twist grip to track the exact throttle opening of the

carburetor.

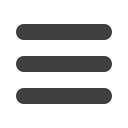

Throttle Index

A.

Place a piece of masking tape access the throttle housing

adjacent to the twist grip so that it is visible from the riding position.

B.

Install a colored push pin or sewing pin into the throttle grip

lange adjacent to the masking tape. Adjust the throttle cable

free play to near zero.

C.

With the throttle closed, make a “0” mark on the masking tape

adjacent

to the pin head on the throttle lange.

D.

Open the throttle all the way and make a “W.O.T” mark on

the masking tape adjacent to the pin head.

E.

Using a tape measure, divide the distance between the

two marks on the tape into quarters and make marks for

each throttle opening on the tape. (0, 1/4, 1/2, 3/4, W.O.T.)

F.

Ride the motorcycle and make mental notes regarding

the carburetion according to the throttle index. If a problem

is truly carburetor related, the symptoms will come and go

according to the throttle position.

3. Work in progression from 0 throttle through full throttle.

Motorcycle carburetor fuel circuits are additive. This means the main

circuit delivery is an addition to the pilot circuit delivery. The pilot

system delivers fuel at all throttle settings, therefore, the timing of the

pilot circuit will have some inluence on the decision to be made

regarding the main circuit. If there is any question about the jetting of

the pilot circuit it should be addressed irst. After the pilot circuit has

been optimized it is then possible to accurately evaluate the main

circuit and it’s related components.

4. Altitude and Temperature

The purpose of the carburetor is to mix air and fuel in a speciic

ratio, by mass, in order to present a combustible mixture to the en-

gine.

Carburetors are generally lexible instruments when used to mix air

and fuel in the proper ratio and will compensate for small changes in

air density. It is when the altitude or temperature becomes extreme

that it will be necessary to re-jet according to atmospheric condition.

Altitude and temperature are important factors to consider

when tuning carburetors for peak performance, as they directly affect

air density. Notes should be taken regarding altitude and temperature

changes as they occur in order to determine which way to go with

carburetor adjustments.

Because air is a fas, its density is directly affected by altitude,

barometric pressure, temperature and humidity. These factors will

increase or decrease air density depending upon where you travel or

how weather patterns develop in your riding area.

Gasoline is a liquid and cannot be compressed. therefore,

its density is not affected by altitude, temperature, or humidity.

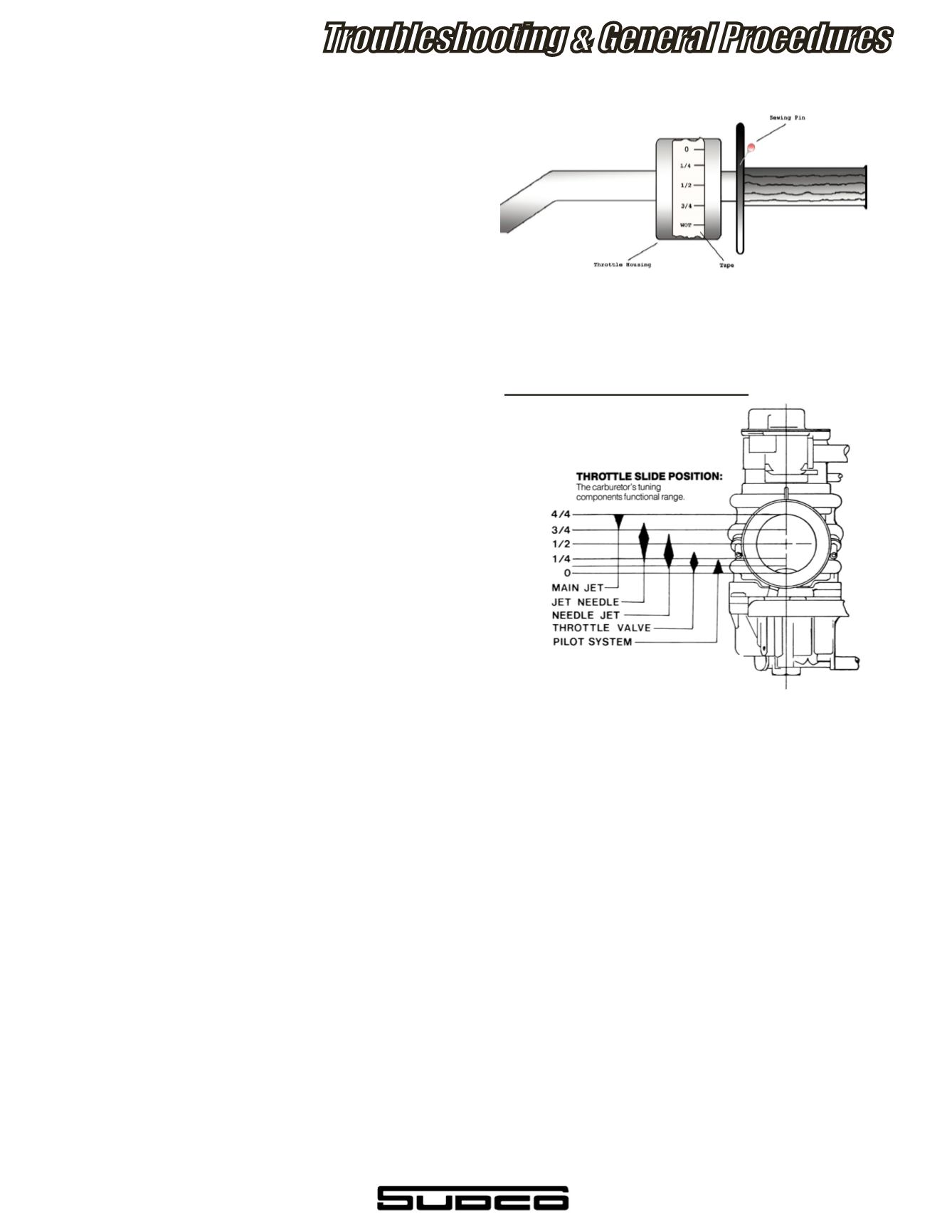

Throttle (Slide) Valve

The Carburetor’s tuning

components functional rate.

Troubleshooting & General Procedures

1.) Throttle Position

Component Functional Range - If re-jetting is required,

irst ind the throttle position where there appears to be a problem.

Then determine if the engine is running rich or lean by using the

Symptoms Chart on the next page.

527